In June 2018, Chinese Scientists were able to 3D print ceramics in microgravity using lunar dust, thereby continuing 10,000 year tradition of exploration in the use of new materials, novel craftsmanship methods and technological innovation in the development of Chinese Ceramics.

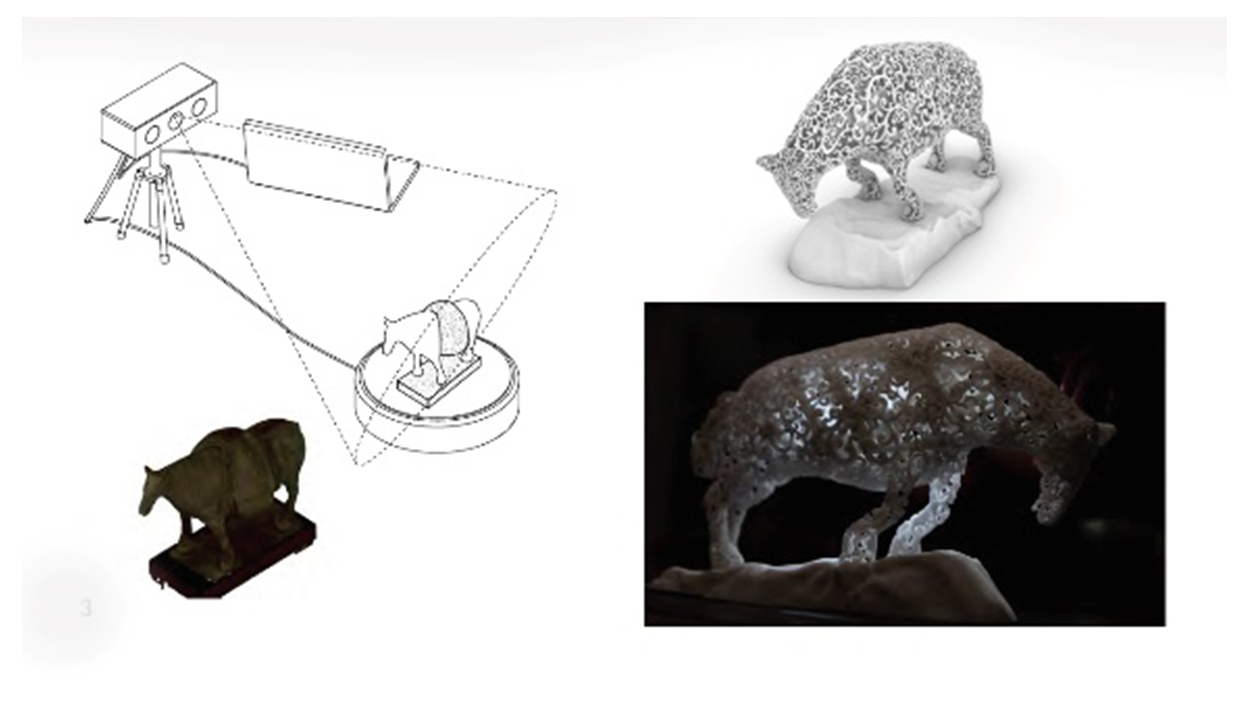

In contrast in the field of conservation and preservation of cultural artefacts, 3D printing is used not to innovate but to replicate either part of damaged artefacts or entire pieces constructed from 3D scans of the originals. The resulting surrogates are often criticized for their inauthenticity. If used only as a replicating technology, 3D printing currently seems to be unable to transfer essential aspects of the craft and material ontology of cultural artefacts such as tool marks, material haptics and the patina of objects which together create the so-called “aura” of cultural objects made by hand.

This research project started with ceramic glazings and their translation into new surfaces

for 3D printing. Now, supported with a second GRF grant, and in collaboration with The Hong Kong University Museum and Art Gallery (UMAG), we continue to investigate transfer methods for Chinese Ceramics. We combine scientific, historical, cultural and technical research to create authenticity in 3D printing that contributes both to the development of digital craftsmanship, to cultural heritage, and to museum collection development and management.

This extended research articulates new forms and material expressions for 3D printing based on the

analysis and adaptation of traditional ceramic production procedures. It includes the modification of the toolpath for 3D printers, new transfer methods from 3D scanned traditional crafted ceramic artefacts to 3D objects, and the development of specific production methods for their 3D printing. This will allow the creation of a transfer of the traditional craft into new ceramics, based on 3D scans of selected artefacts within UMAG’s study collection and lead to a hybridization of the traditional qualities historic artefacts through 3D scanning, and ultimately establish a novel form of museum collection.

Grants

GRF: Science + Technology + Arts (STArts) Digital Craftsmanship in Art and Design - Chinese Ceramics (9043267) $217,889

GRF: New Media Ceramics – Analysis and Methodical Transfer of Craftsmanship Techniques from Chinese Ceramic Painting to the Development of New Glazing for 3D Printed Substrates (9042734) $329,890

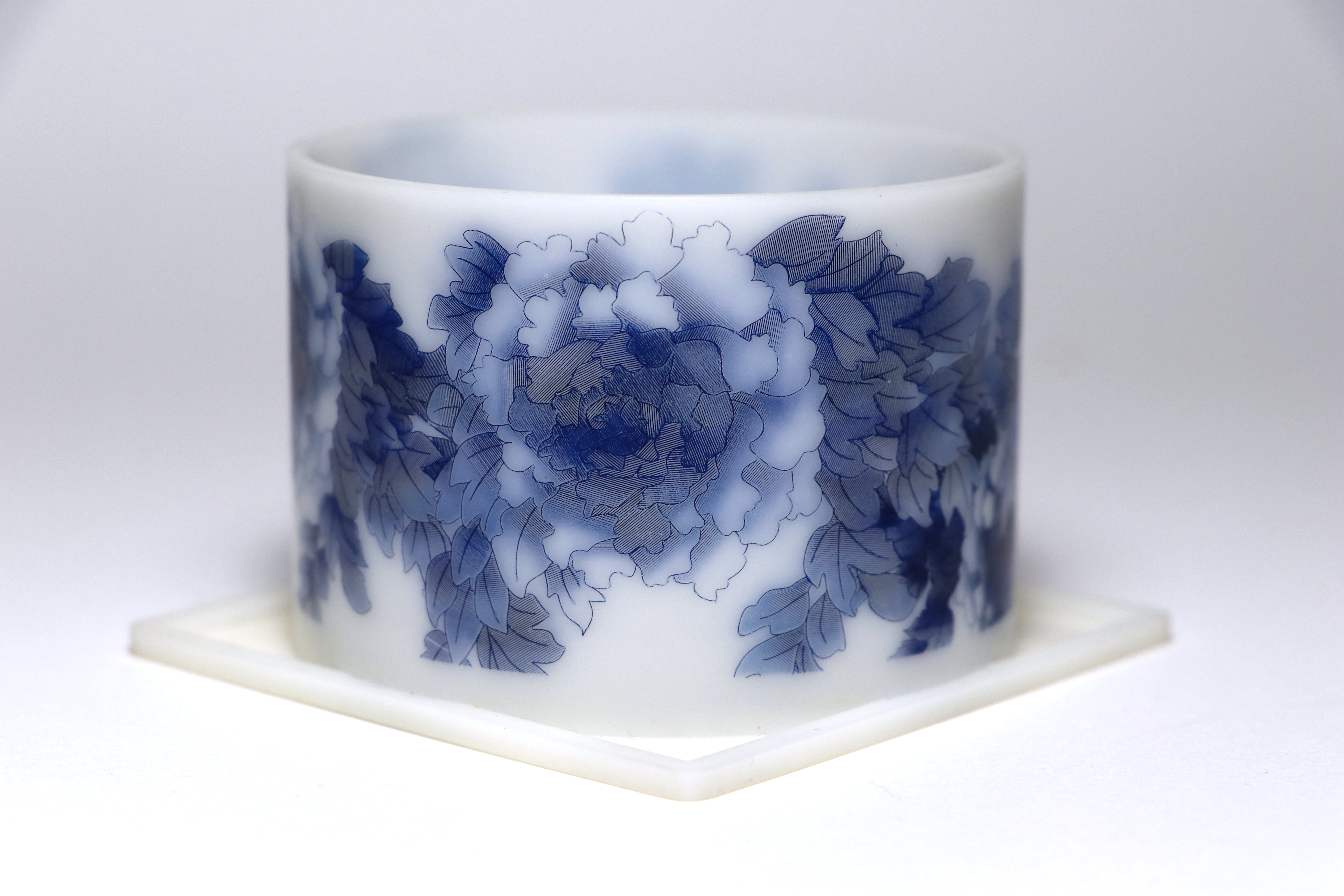

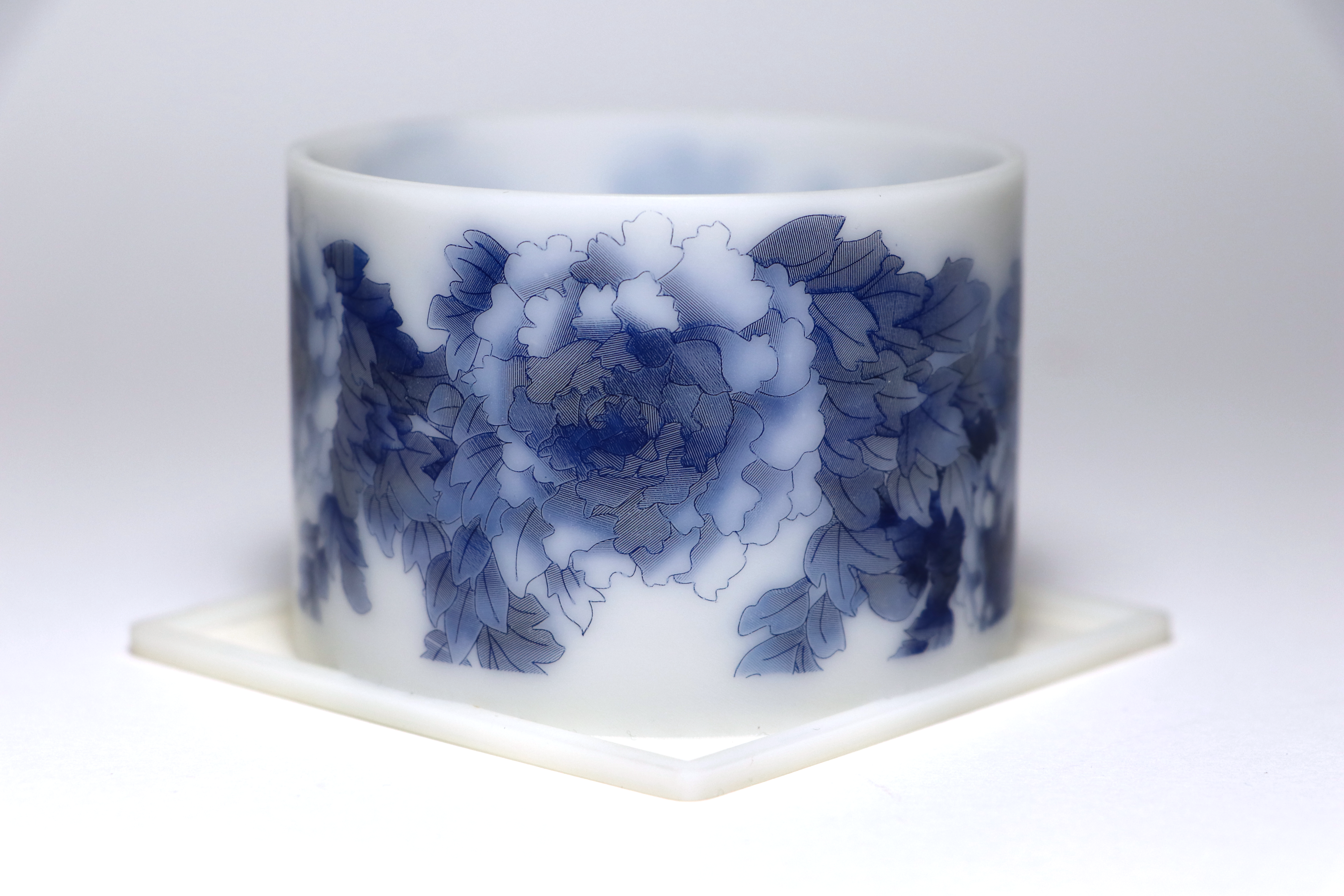

3D UV activated surface of FDM printed single curved geometry via custom made CNC 3 axis laser application with a precision of 0.05 mm articulating brush strokes used in Chinese ceramic glazes.

3D UV activated surface of FDM printed double curved geometry via custom made CNC 3 axis laser application.

The Tang Dynasty Tomb Figures transitioning Chinese Ceramics into critical design (Inventory Number: HKU.C.1953.0038), Student example of the first collaboration with UMAG

Glass Entanglement VII, Exhibited at the Solo Museum exhibition, Metamorphosis or Confrontation, University Museum and Art Gallery 20th May - 20th November 2020. The work is placed on a lacquer carved table from the museum collection, articulating a digital craftsmanship genealogy bridging 300 years - highlighting the relation between traditional and contemporary methods in craft.

Exhibitions

Metamorphosis or Confrontation

Curators: Klein, T., Knothe, F. & Kraemer, H., Retrospective Solo Exhibition of the works of Tobias Klein at the University Museum and Art Gallery (UMAG), Hong Kong, 20th May - 6th Dec. 2020

Identities & Fractures

Curators: Klein, T. & Kraemer, H., Solo Exhibition at the Goethe-Institut Hong Kong, Hong Kong, 12th Dec. 2019 - 25th Jan. 2020

Through the Looking-Glass

Exhibition at PRS Asia 2019, examination of the PhD, Osage Gallery, Hong Kong, 20 – 25 September 2019

Conferences

ISEA 2018, ISEA 2019

SIGGRAPH 2018, SIGGRAPH 2020, SIGGRAPH 2021